Rigid metal-organic framework as a molecular sieve for ethylene

9 November 2018

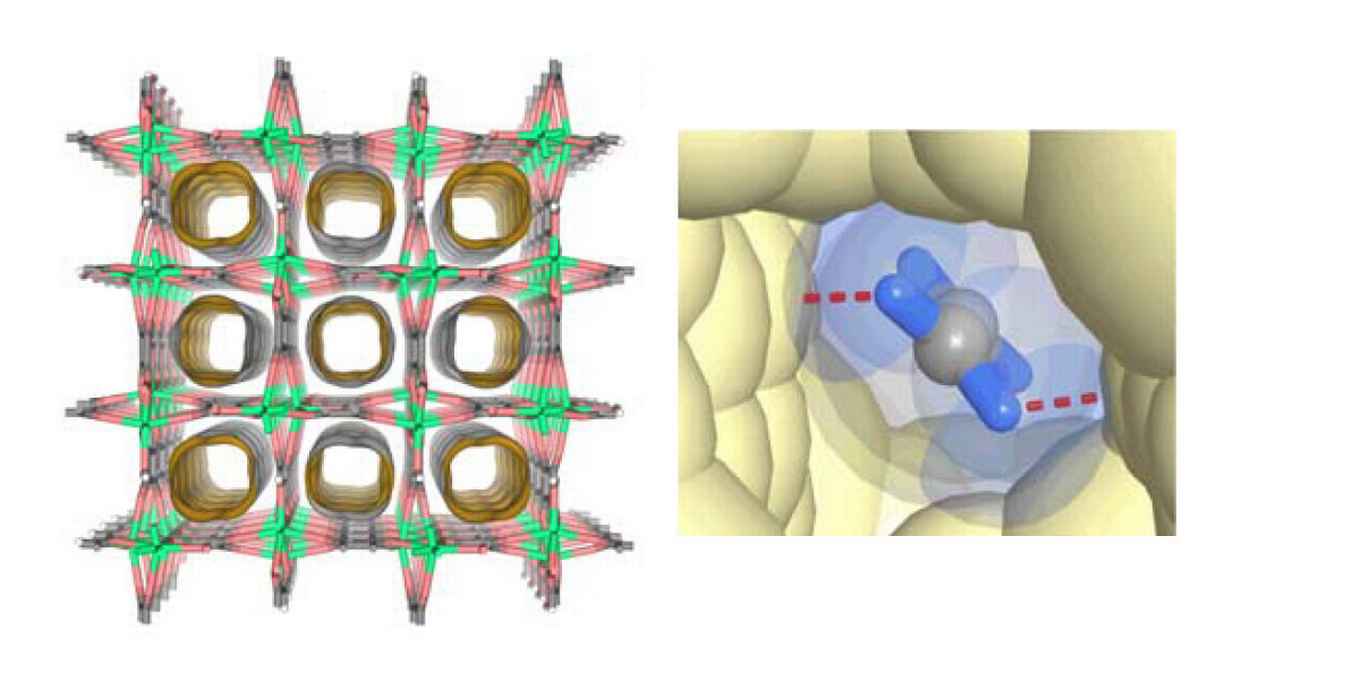

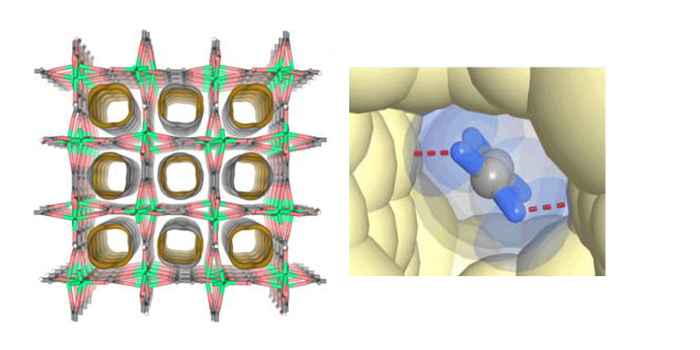

The novel metal–organic framework possesses rigid one-dimensional channels with apertures that are of a similar size to ethylene molecules. But owing to the size, shape and rigidity of the pores, they act as molecular sieves to prevent the transport of ethane. This holds the promise of energy efficient separation of ethylene/ethane mixtures which is currently one of the most energy-intensive processes in the chemical industry.

The efficiency of the molecular sieve for the separation of ethylene/ethane mixtures was validated by breakthrough experiments with high ethylene productivity under ambient conditions. Prof. Rajamani Krishna of the University of Amsterdam's Van 't Hoff Institute for Molecular Sciences contributed to the research with transient breakthrough simulations using the methodology he described in 'Screening Metal-Organic Frameworks for Mixture Separations in Fixed-Bed Adsorbers using a Combined Selectivity/Capacity Metric', published in 2017 in RSC Advances. The simulation details were consistent with the experimental data.

Easily synthesized

The MOF was created at The University of Texas at San Antonio (USA) and China's Taiyuan University of Technology and studied at the NIST Center for Neutron Research (NCNR) in Gaithersburg, USA. The material can be easily synthesized from calcium nitrate and squaric acid, resulting in a molecular sieve of the composition [Ca(C4O4)(H2O)].

Since the material can be easily synthesized at the kilogram scale using an environmentally friendly method and is water-stable, the researchers foresee potential of the MOF for industrial implementation. The strategy of using highly rigid metal–organic frameworks with well-defined and rigid pores could also be extended to other porous materials for chemical separation processes.

Recently the same research team reported in Science on the development of another MOF to which Rajamani Krisna also contributed with calculation and simulations. That MOF uses a distinctly different separation principle and selectively adsorbs ethane where the MOF reported in Nature Materials is in fact an ethylene sieve. Combined, the Science and Nature Materials papers offer two completely different separation strategies to provide energy-efficient alternatives to current distillation technology.

Publication details

Rui-Biao Lin, Libo Li, Hao-Long Zhou, Hui Wu, Chaohui He, Shun Li, Rajamani Krishna, Jinping Li, Wei Zhou, Banglin Chen: Molecular sieving of ethylene from ethane using a rigid metal-organic framework. Nature Materials (2018), published online 05 November 2018 DOI: 10.1038/s41563-018-0206-2