Enzymatic dissolution of lignin in water

15 May 2017

Lignin is a natural compound that give plants and trees their strength and flexibility. It is one of the most abundant organic polymers on Earth - trees are on average twenty-five percent lignin. What’s more, lignin is rich in so-called aromatics - a class of chemical building blocks for a range of important chemicals and polymers.

Chemists are interested in using lignin as a source of aromatics for sustainable chemical processes (using bio-based raw materials rather than oil, gas, or coal). To its advantage, lignin is easily available as a major by-product of the pulp and paper industry. However, a major drawback is the cumbersome processing of lignin due to the fact that the biopolymer is hardly soluble in water. It requires the use of caustic solutions, ionic liquids, or supercritical solvents that are relatively costly and generate substantial waste.

Enzymatic chemistry

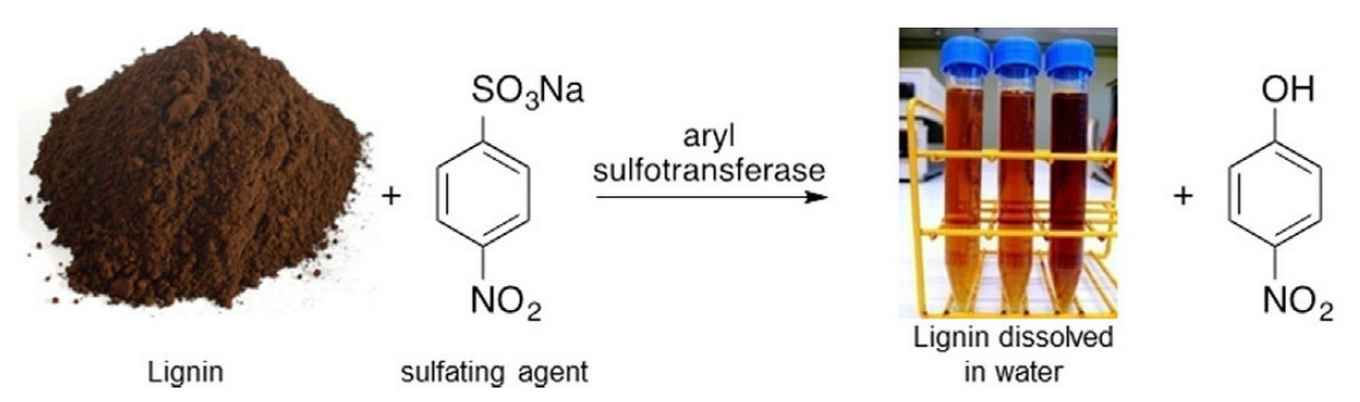

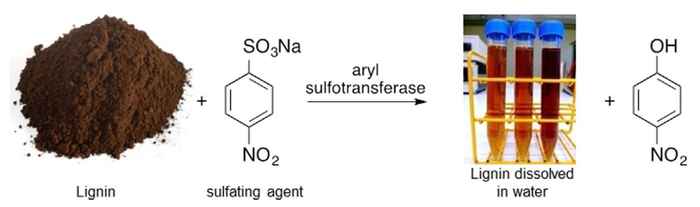

Now, researchers of the Van 't Hoff Institute for Molecular Sciences of the University of Amsterdam, part of its Research Priority Area Sustainable Chemistry, have developed an enzymatic process that renders lignin much easier to dissolve. The process is based on the finding of emeritus professor Ron Wever's Biocatalysis group that a bacterial enzyme (aryl sulfotransferase) can add sulfate groups (taken from p-nitrophenylsulfate) to the hydroxyl groups of phenolic aromatic compounds.

The Heterogeneous Catalysis and Sustainable Chemistry research group of professor Gadi Rothenberg has applied this enzymatic chemistry to lignins. As a result the sulfated lignins dissolve fairly easily in mildly alkaline solutions. The new method outperforms existing lignin sulfating processes as well as the commonly applied methods for lignin dissolution.

The new enzymatic method is robust and applies to various types of lignins. Remarkably, the kinetics of the sulfation reaction can be easily monitored qualitatively and quantitatively using UV/Vis spectroscopy. The simple quantification technique, combined with the fact that these enzymatic sulfation reactions run under ambient conditions, make this method a practical and promising tool in biomass valorization.

Publication:

Pepijn Prinsen, Anand Narani, Aloysius F. Hartog, Ron Wever, and Gadi Rothenberg: Dissolving Lignin in Water through Enzymatic Sulfation with Aryl Sulfotransferase. ChemSusChem 2017, DOI: 10.1002/cssc.201700376